Oil and gas conveying technology

thyssenkrupp rothe erde produces special slewing bearings with enormous diameters of up to 18 metres for the oil conveying industry’s mobile production, storage and loading units. These bearings are manufactured partially segmented. They connect oil tankers with the deposits. A turret is mounted on the inside, through which pipes are directed from the ship to multiple oil sources on the seabed. Thus, the conveying pipes do not even turn when changing position.

Our solutions in the field of oil and gas conveying technology

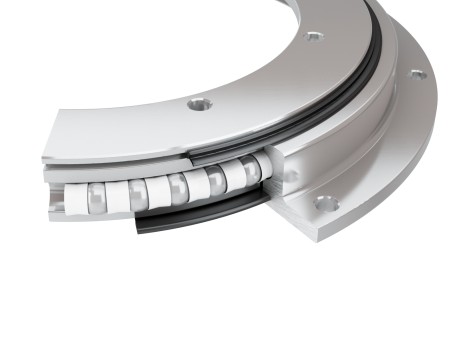

A Floating Production Storage and Offloading Unit (FPSO) is a floating structure equipped with crude oil processing and storing facilities. Generally, converted oil tankers are used as FPSO units. From the bottom of the ocean, the oil gets to the winding tower on the top of the FPSO unit via risers, and from there to an oil tanker close by. The unit must be able to follow the movement of the waves and influence of current, without putting strain on the risers. This is achieved using a Turret-Mooring-System with a rothe erde® slewing bearing. It consists of two main components: The main bearing absorbs the loads and makes it possible for the FSPO unit to rotate freely around the anchor chains. The swivel bearings prevent individual risers from twisting.

High-quality bearings with special dimensions are needed for vertical pipe handling. thyssenkrupp rothe erde has developed the perfect slewing bearings for this field, drawing on its many years of experience in the on-/offshore field.

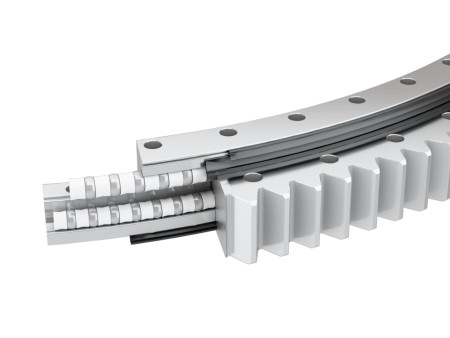

The loading and unloading of oil tankers occurs both in ports and remote sea areas, such as the Barents Sea or the North Sea. This places high demands on taking measures to ensure the safety of employees and the protection of the environment. Transfer systems must always be able to reliably transport the combustible raw materials, oil and gas. There are different transfer systems to suit different environments. Slewing bearings made by thyssenkrupp rothe erde, as the central components needed for safe loading and unloading are the common denominator.

Loading or unloading oil and gas directly onto conveying or production sites is not always possible in flat bodies of water, especially for large tankers. In these cases, stationary underwater pipelines are used, which are linked to clearly defined transfer points with Single Point Moorings (SPM). At SPMs, there are large buoys, firmly anchored to the seabed. They connect tank ships of any size to underwater pipelines.

In this process, slewing bearings made by thyssenkrupp rothe erde ensure that the upper part of the buoy remains aligned with the tanker when the oil and gas is being removed.

/thyssenkrupp_logo_claim_d.svg)