Packaging and filling machines

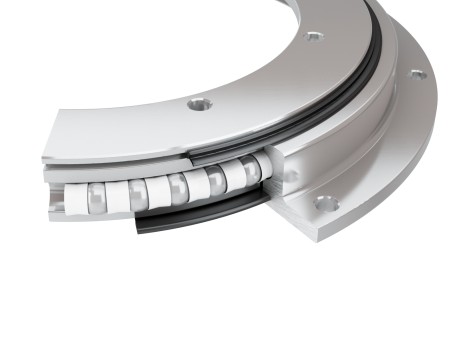

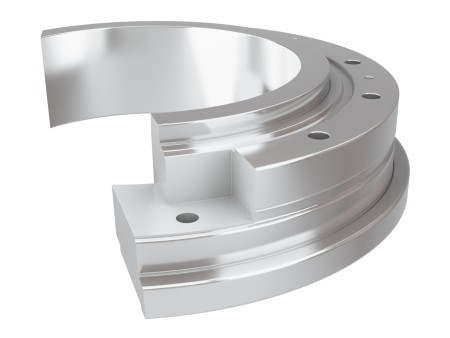

To securely transport products of all kinds, modern packaging machines are indispensable. They are used to pack the most varied of goods and liquids in many different variations and as special solutions, for example, as bottle and can fillers, sealing machines or film winders. Packaging machines must meet two main requirements: Both high throughput and low waste. Continuously rotating slewing bearings help with this: They minimise wear caused by the packaging process and ensure the machines attain a long service life.

Our solutions in the field of packaging and filling

Liquids can be automatically inserted into cans or bottles using filling machines. Compared to linear variants, the carousel-based set up has established itself as an undeniably faster and more efficient filling solution. Slewing bearings made by thyssenkrupp rothe erde, among other elements, make this type of filling machine possible by guaranteeing the continuous concentricity of the system.

Using sealing machines, containers of all sorts can be sealed in a fully automated, efficient and secure manner. Generally, the machines are integral parts of modern filling machines. Containers are moved to the individual stations on large rotating carousels and conveyor belts. Our slewing bearings ensure this operation runs smoothly.

In packaging technology, products are protected for further processing or transportation using paper, film or fleece. Film winders, also called unwinders, are used here. With these, products of all shapes and sizes can be packed. Our slewing bearings ensure the safe and reliable turning of the rotation axis in these machines. Moreover, their low friction levels mean wear and tear is minimised. This ensures the film winder’s faultless and, thus, long-lasting operation.

/thyssenkrupp_logo_claim_d.svg)